Metallic finishes in automotive painting present unique challenges requiring advanced techniques and specialized knowledge for precise color matching. Collision repair centers use spectral analysis and specialized color sensors to accurately identify and reproduce complex metallic shades like silver or bronze, ensuring seamless blends and maintaining vehicle aesthetic integrity through unparalleled precision color matching.

In the realm of industrial finishes, achieving precise color matching for complex metallic coatings is an art met with growing demand. This intricate process involves understanding unique metallic properties and overcoming challenges inherent in their diverse appearances. With advancements in technology, spectral analysis emerges as a game-changer, enabling accurate color measurement and matching. This article explores these intricacies, delving into the science behind precision color matching for complex metallic finishes, and the techniques that ensure consistent, visually stunning results.

- Understanding Metallic Finishes: Properties and Challenges

- The Role of Spectral Analysis in Color Matching

- Techniques for Achieving Accurate Color Replication

Understanding Metallic Finishes: Properties and Challenges

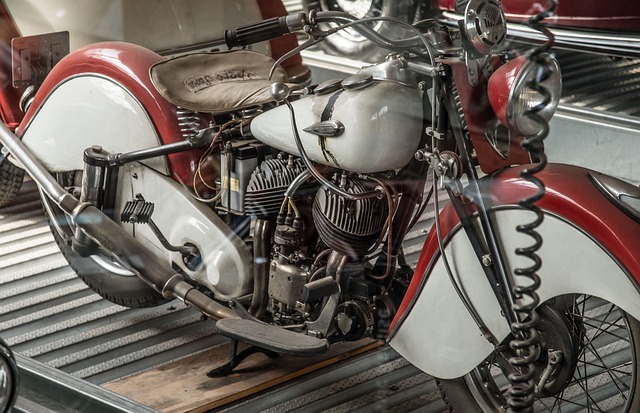

Metallic finishes are a complex and visually captivating realm in the world of automotive painting. These finishes, often seen on modern vehicles, offer a deep, lustrous appearance that goes beyond traditional colors. However, achieving precision color matching for such intricate finishes presents unique challenges. Metallic pigments contain microscopic particles that reflect light in different ways, creating a dynamic range of hues that can shift under varying lighting conditions. This complexity demands advanced techniques and specialized knowledge from professional painters.

In collision repair centers or scratch repair services, the goal is to match not just the color but also the metallic effect. Car scratch repair experts must consider factors like the base coat’s composition, the type of metallic pigment used, and how light interacts with these layers. This requires a keen eye for detail and often involves custom mixing and application techniques to ensure a flawless finish that blends seamlessly into the existing surface, be it a sleek silver, vibrant bronze, or any other complex metallic shade.

The Role of Spectral Analysis in Color Matching

In the realm of automotive repair, especially when it comes to Mercedes Benz repair and car bodywork, precision color matching is paramount for achieving a flawless finish. Spectral analysis plays a pivotal role in this process by breaking down the complexities of metallic finishes into measurable components. This advanced technique involves examining the reflected or emitted light from a surface at various wavelengths, providing an exacting measure of its color composition.

By employing spectral analysis, technicians can accurately identify and replicate the intricate nuances found in complex metallic finishes. This ensures that every panel, from door to hood, matches seamlessly, maintaining the vehicle’s aesthetic integrity. In automotive repair services, where attention to detail is paramount, spectral analysis acts as a powerful tool, enabling experts to achieve unparalleled precision color matching for even the most demanding car bodywork projects.

Techniques for Achieving Accurate Color Replication

Achieving accurate color replication in complex metallic finishes is a delicate art that requires meticulous techniques and precision color matching. Professionals in automotive restoration, auto body repairs, and collision repair services employ advanced tools to ensure perfect color coordination. One such method involves utilizing specialized color sensors that measure light reflection with microscopic accuracy, capturing the exact hue, tone, and saturation of the desired finish.

These sensors are hand-held devices that can quickly scan different areas of a part, providing real-time data for comparison. By comparing the scanned data to a known standard or a digital color profile, technicians can make precise adjustments to the mixing ratios of pigments and dyes, resulting in a near-perfect match. This meticulous approach ensures that the restored or repaired surface not only looks identical but also maintains the original metallic sheen and depth, enhancing the overall quality of the work.

Precision color matching for complex metallic finishes is a multifaceted challenge, but with the right tools and techniques, it becomes an achievable goal. By understanding the unique properties of metallic coatings and leveraging advanced spectral analysis, professionals can ensure accurate color replication across diverse applications. Continued advancements in technology, such as innovative measurement methods and sophisticated material science, are revolutionizing this field, enabling more consistent and durable results. This, in turn, elevates the quality and aesthetic appeal of products ranging from automotive bodies to high-end electronics, ultimately satisfying the ever-growing demand for precise color matching in complex metallic finishes.