In the automotive sector, especially for luxury brands like Mercedes Benz, precise color matching during repairs is vital for aesthetics and vehicle value. Advanced precision color matching techniques overcome lighting, manufacturing, and material challenges, ensuring restoration meets or exceeds expectations. This technology revolutionizes operations by accurately replicating colors during frame straightening and body repairs, eliminating costly touch-up processes, saving time, money, and enhancing customer satisfaction while significantly reducing waste and material costs.

Precision color matching is a game-changer for production processes, saving time and money while enhancing quality. In today’s competitive market, understanding the intricacies of color matching issues is crucial. This article delves into the challenges faced in production and explores how advanced precision techniques offer accurate results from the outset. By streamlining processes through effective color matching, businesses can achieve significant cost savings, making it an indispensable strategy for efficient operations and successful outcomes.

- Understanding Color Matching Issues in Production

- The Power of Precision: Accurate Results from the Start

- Cost Savings: Streamlining Processes Through Color Matching

Understanding Color Matching Issues in Production

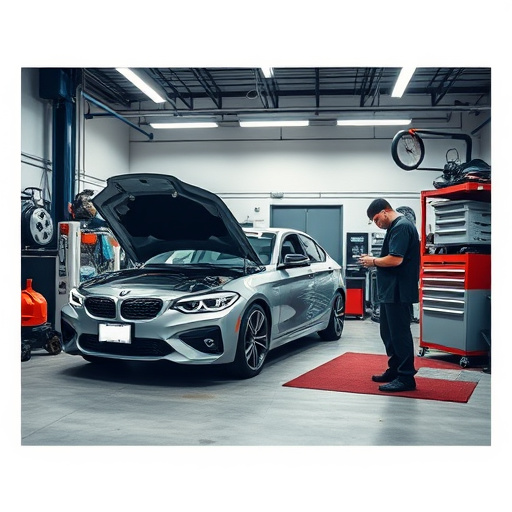

In the fast-paced world of production, especially in industries like automotive, where precision and quality are paramount, understanding color matching issues is key to efficiency. When it comes to luxury vehicle repair, such as those seen in Mercedes Benz models, accurate color matching ensures that each car looks as good as new after repairs or refinishing. However, achieving precise color matching can be challenging due to various factors: variations in lighting conditions, differences in manufacturing processes, and the inherent characteristics of different materials.

These challenges lead to inconsistencies, resulting in repaints that may not perfectly match the original color, especially over time under varying environmental conditions. For mercedes benz repair or other luxury vehicle repairs involving paintwork, this can be particularly problematic as it compromises the car’s aesthetic appeal and value. Thus, adopting precision color matching techniques is a game-changer, ensuring that every repair job meets or exceeds expectations for both customers and professionals in the industry.

The Power of Precision: Accurate Results from the Start

In today’s competitive market, every second counts for businesses, especially in time-sensitive sectors like automotive repair. The Power of Precision: Accurate Results from the Start highlights how advanced technologies like precision color matching can transform operations at car repair shops and bodyshops. By employing this method, professionals can achieve exact color replication on vehicles undergoing frame straightening or car body repair, eliminating the need for lengthy and costly touch-up processes.

Precision color matching streamlines the process, ensuring that repairs are not just visually appealing but also perfectly aligned with the original vehicle’s aesthetics. This level of accuracy saves both time and money, as it reduces the frequency of rework and enhances overall customer satisfaction.

Cost Savings: Streamlining Processes Through Color Matching

One of the most significant benefits of precision color matching is its profound impact on cost savings within various industries, particularly those involving automotive repairs and refinishing. Traditional color-matching methods often relied on manual mixing, which was time-consuming and required a high level of expertise. With precision technology, this process becomes highly streamlined. By utilizing advanced instruments and software, technicians can quickly and accurately match colors, eliminating the need for excessive trial and error. This efficiency is particularly noticeable in auto collision centers where car bodywork repairs are common; precise color matching ensures that each repair matches seamlessly with the original vehicle’s finish, reducing the time spent on touch-ups and refinishing.

Furthermore, precision color matching minimizes waste, which translates to substantial financial savings. In the past, incorrect color choices often resulted in discarded materials or the need for additional resources. Now, auto body shops can achieve perfect matches with fewer attempts, cutting down on the cost of unused paints and materials. This is especially valuable when addressing car scratch repair processes, where quick and accurate color matching ensures a more efficient restoration without unnecessary expenses.

Precision color matching is a game-changer for any production process, offering significant time and cost savings. By understanding and leveraging the power of accurate color matching from the outset, businesses can streamline their operations, reduce waste, and enhance overall efficiency. This innovative approach ensures that every product meets high-quality standards, delivering exceptional results while keeping costs low. Embrace the precision of color matching to revolutionize your production process today.